quality & structure.

longevity & robustness

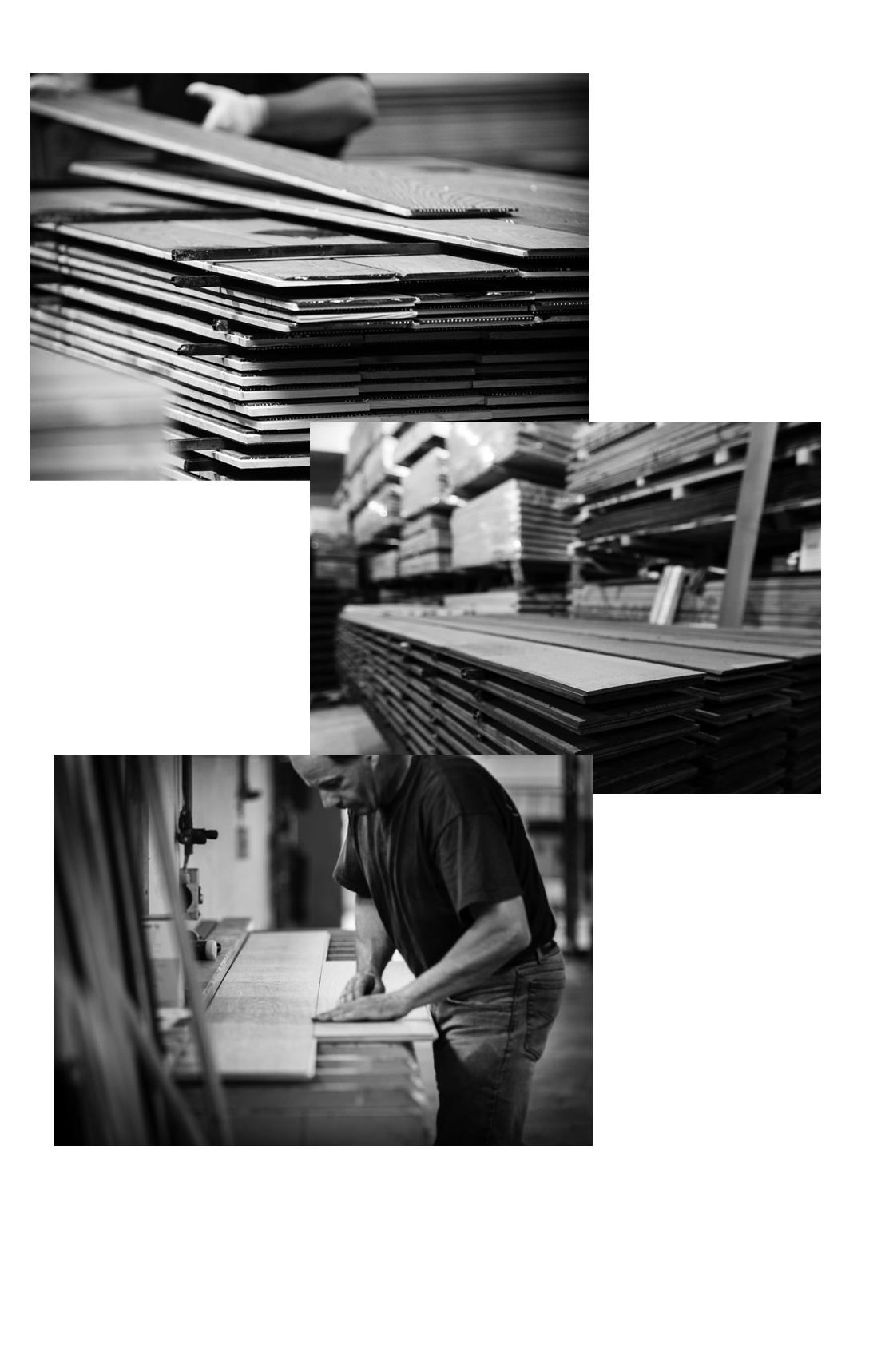

What sets Mafi timbers apart from other timber products is the superior quality and structure of each timber floor board.

Each board is hand crafted, passing through at least 44 sets of hands to assure a timber board with structural integrity and longevity.

The boards are made up of a 3-layer construction. The top and bottom layers are the same wood, ensuring perfect balance and preventing warping or cupping over underfloor heating. The middle layer is a fast growing conifer and runs across the grain for added strength.

The product is true to Mafi’s sustainable approach, with a no compromise, lacquer free, all-natural finish and all-natural glue. A naturally finished timber flooring means the wood can still breathe, regulating the humidity and cleaning the air. Further to this, it is scratch proof and stiletto proof!

No harmful chemicals are used in the production of Mafi products, protecting you from harmful toxins released from chemically treated timber products.

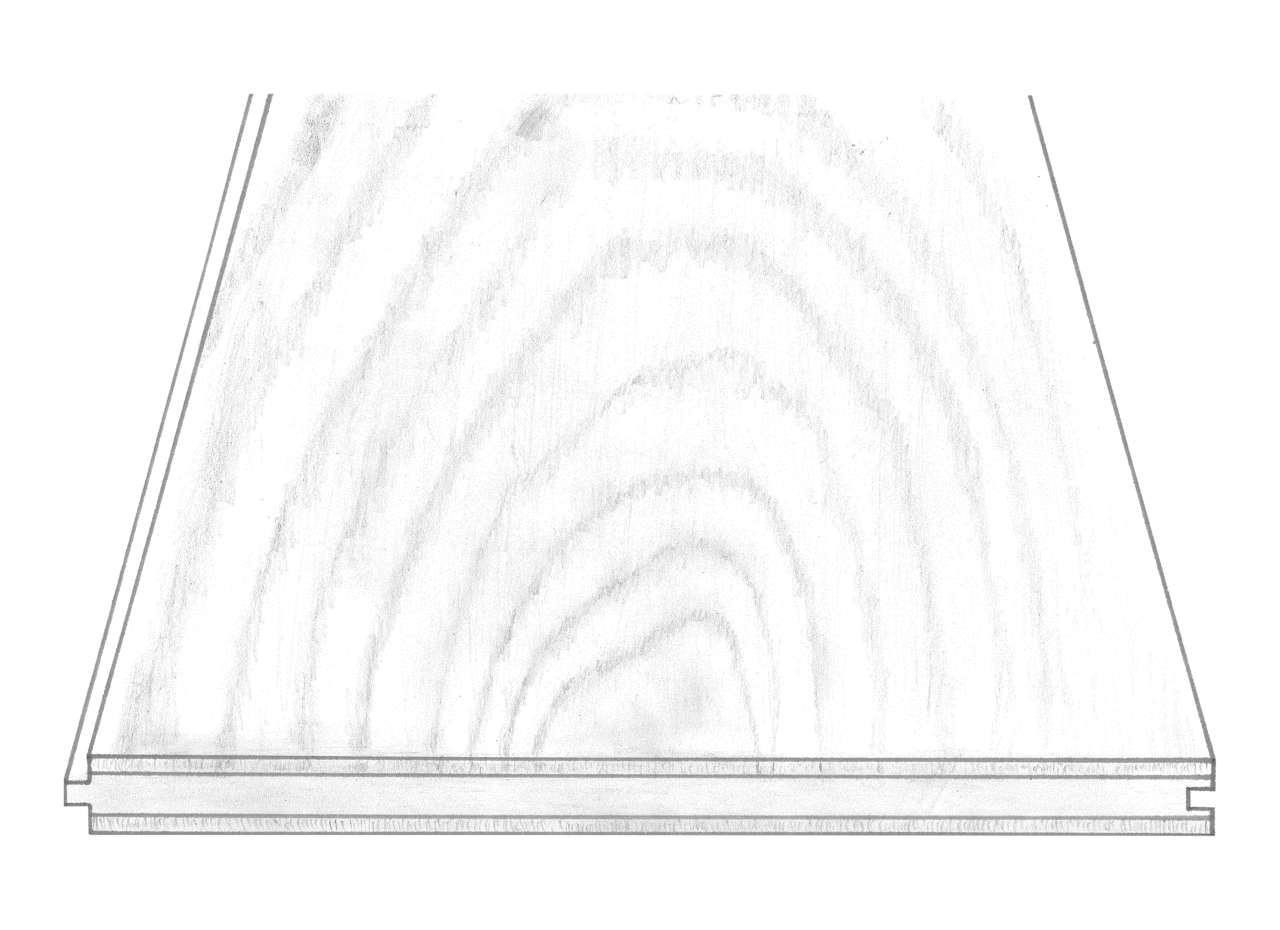

symmetrical 3-layer construction

The facts:

– Top layer and back layer from the same wood in the same thermo treatment

– Middle layer from Spruce cross-glued 90°

– Bonding with formaldehyde-free white glue

The advantages:

– very high stability

– reduced risk of gaps

– ideal for installation on underfloor heating

– wide range of applications

– imposing dimensions of up to 5 metres in length and widths of 300mm possible

– optimum resource usag

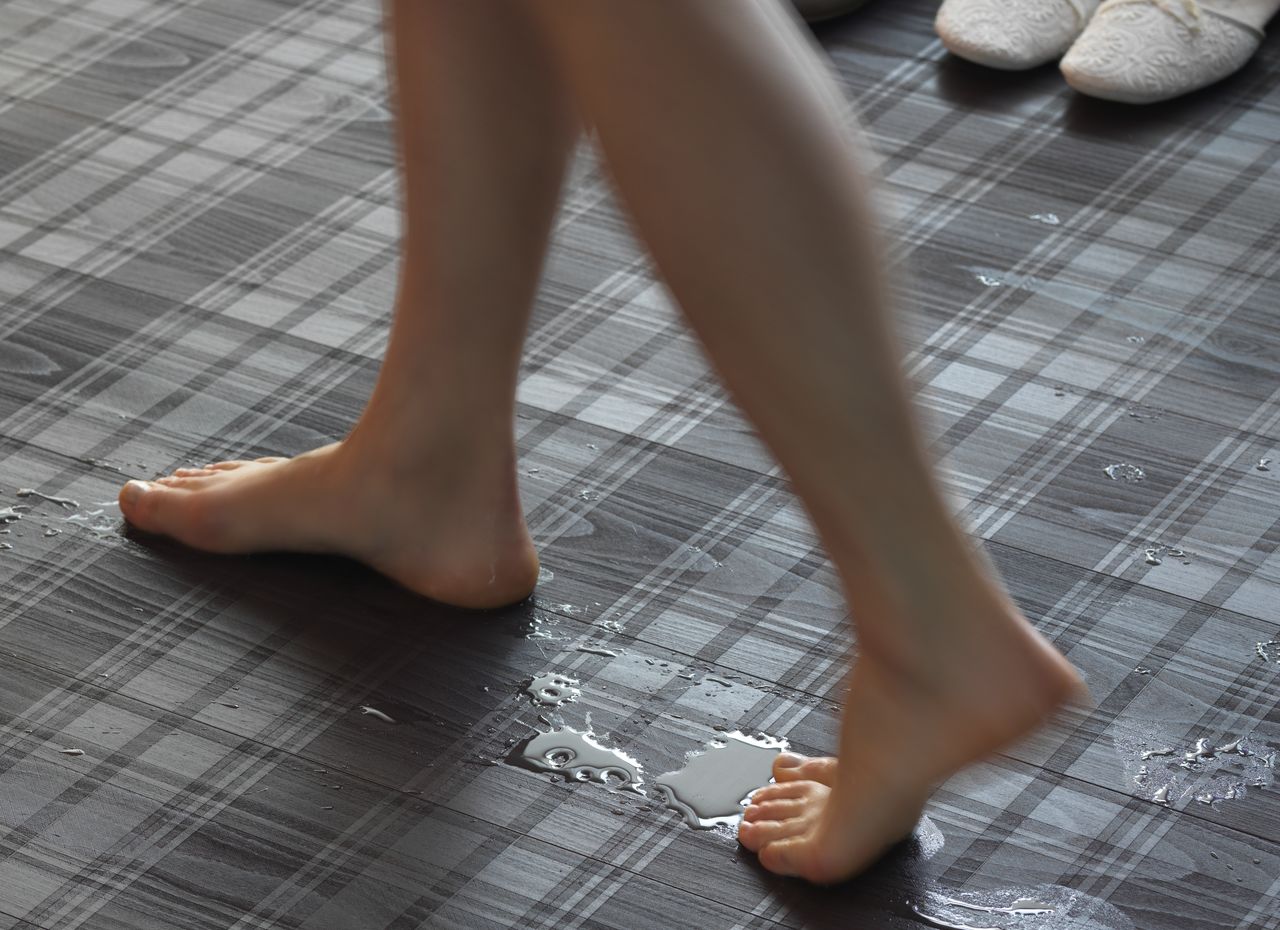

a real barefoot floor

The visible surface of the planks is probably the most distinctive feature of parquet floors. The differences in quality are enormous, even more the effects on room climate and the body. Thus, people are in direct contact with the wood and thus always find a body temperature surface. Wood gives off heat much slower than for example lacquered surfaces. This special finishing procedure allows the pores of the wood to remain open, so that the wood can absorb moisture but also easily dissipate it. Because the floor is not covered with a film, any repairs can be performed locally, without affecting the entire area – in practice a very useful product feature.

the construction in detail

The mafi typical 3-layer symmetrical construction consists of the top and back layers from the same wood in the same thermo treatment. The result is an equally strong counter-move, which greatly reduces the movement of the wood (swelling and shrinkage behaviour). The middle layer consists of an Austrian Pine cross-glued at 90°, which ensures extra stability. The softwood provides for a certain degree of flexibility, which reduces tension in the plank.

Symmetry guarantees stability

The sum of these characteristics allows even more intense use of the wooden floor, such as on underfloor heating with the associated risk of gaps or also the use in bathrooms. Even when installing, there are more possibilities starting with different installation methods up to the topic of reduction of expansion gaps. Please note the mafi installation instructions.

what types of parquet construction are there?

The construction is a decisive factor in the longevity and stability of the planks. Generally, we distinguish between solid parquet and multi-layer parquet. Solid wood parquet uses the same piece of wood across the entire thickness. The swelling and shrinkage behaviour or the warping of the floor represents the largest problem with this type of construction. Underfloor heating increases this problem. Multi-layer parquet consists of different layers starting from the top layer. After that, mostly softer, less expensive woods are used as carriers. High-quality parquet floors have a counter-move and thus consist of three layers.

How does the mafi contruction differ form other products?

You can see a high-quality parquet floor construction with a symmetrical 3-layer construction. The symmetry is that both the visible top layer, and the back layer, also called the counter-move, must consist of the same wood and same treatment. This greatly reduces the natural movement of the wood across the width. The middle layer, in corresponding thickness’ and large softwood boards, should be glued at a 90° angle to the slats. Symmetrical 3-layer planks have far fewer gaps and are ideal for rooms with underfloor heating.